Create unique terrazzo for your project

The appearance of the Circular Terrazzo depends on what material is available in the demolition property. Together with us, architects, designers and property developers get the opportunity to produce their unique terrazzo in our TerrazzoLab.

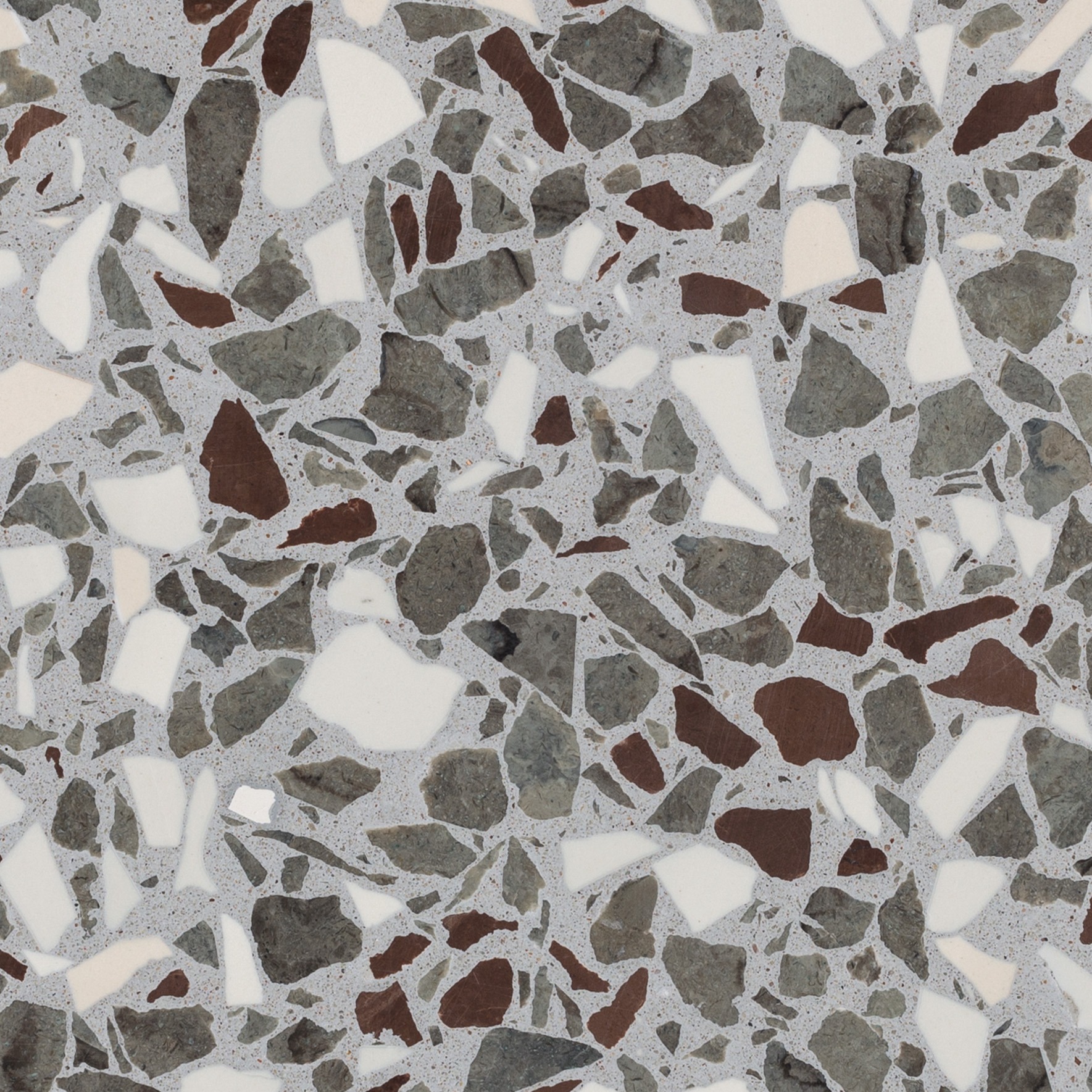

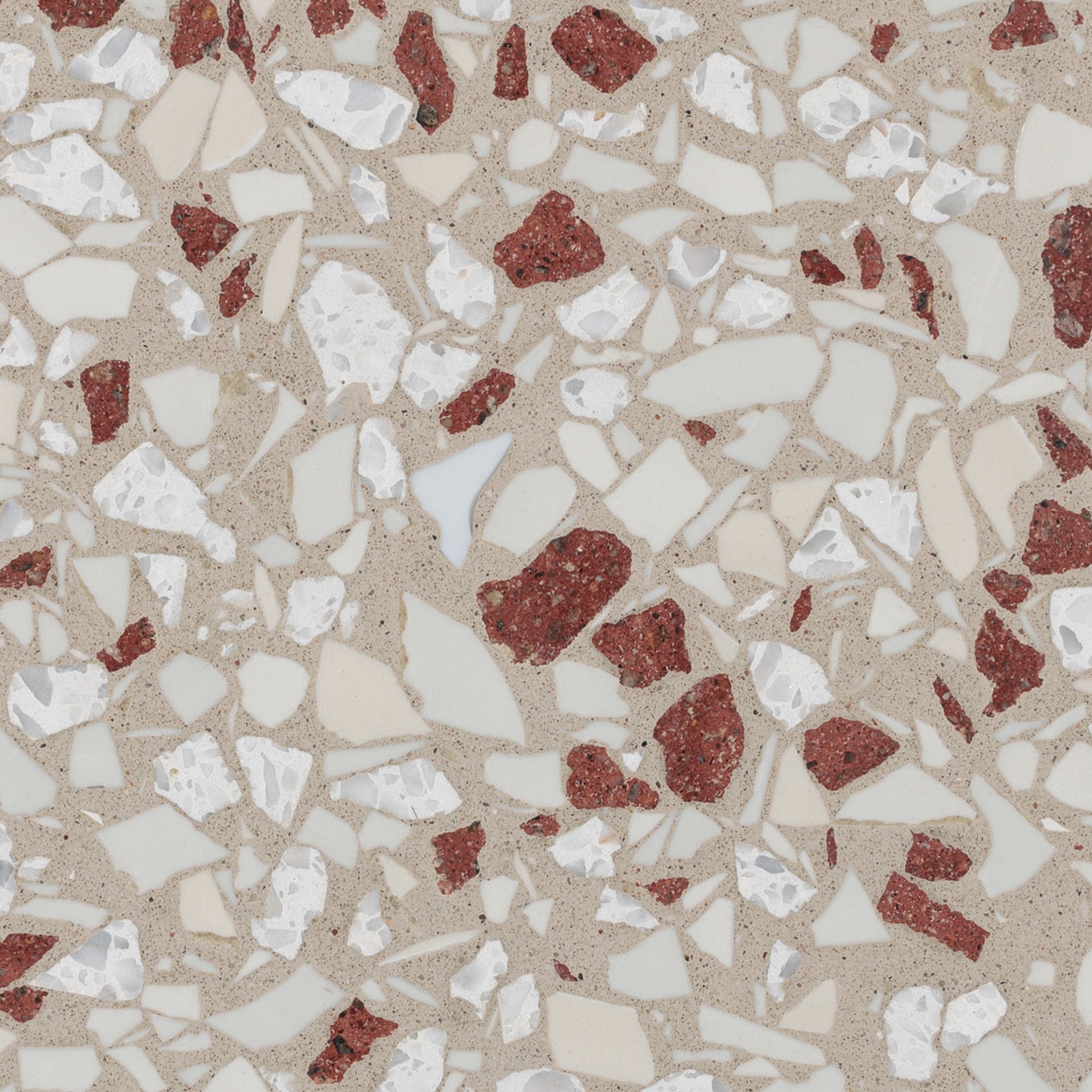

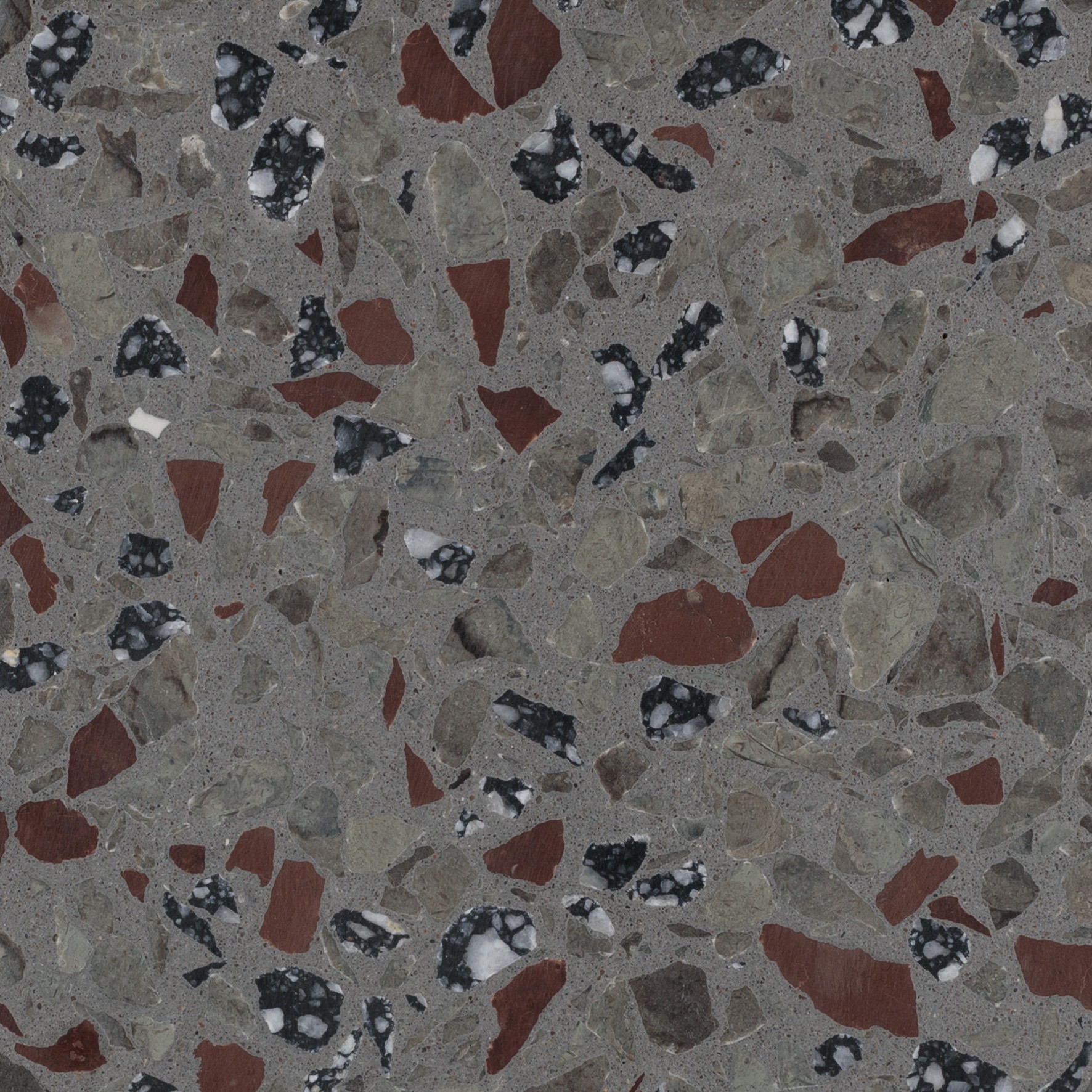

It is thrilling to see how the different materials get different expressions depending on the chosen bottom colour. The images below show samples containing, among other things, crushed concrete tiles, limestone tiles, porcelain and terrazzo tiles.

Circular terrazzo reference - Filipstad Brygge 1, Oslo

More pictures here!

More pictures here!

More pictures here!

More pictures here!